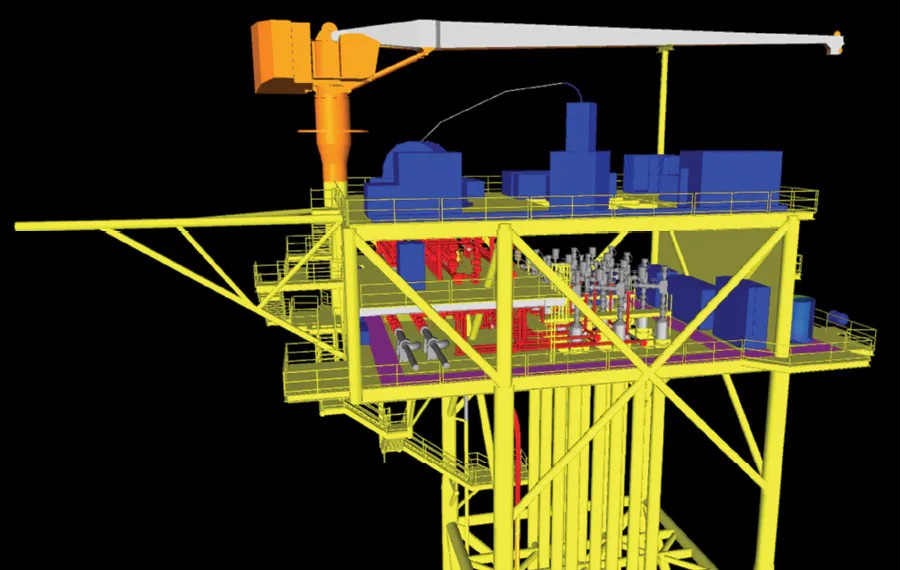

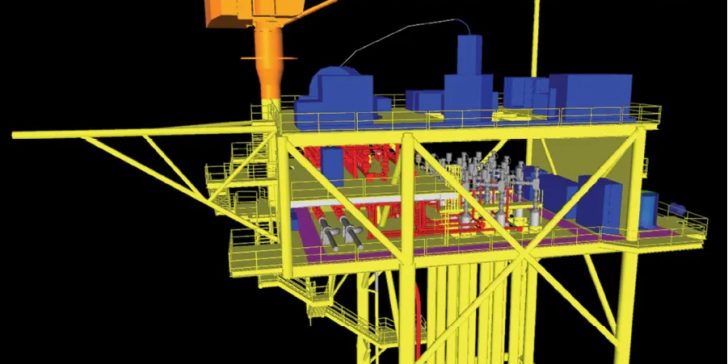

New technologies have been developed to meet industry demands in the constantly evolving world of oil and gas exploration. One such advancement is modular equipment that can be shipped in pieces to easily adapt to harsh conditions at sea before being assembled on location. Once in place, these units add a considerable amount of value for operators. Here are five reasons why you may want to consider this type of technology for your business:

1) Maximize Productivity

One major benefit of modules is their ability to provide well intervention services and help boost overall productivity in deepwater basins. Each unit has a designated function allowing the maximum level of extraction from wells at sea. For example, drilling equipment modules could be used simultaneously with wellheads and manifolds if they were positioned together on a single vessel. In contrast, if they were in separate units delivered to a field, different vessels would need to be used, resulting in more time and higher costs for the overall project.

2) Save On Overall Costs

In addition to saving on transportation expenses, using modules from various companies, such as PRT Offshore can help operators save money by reducing site preparation work and simplifying installation procedures. On a large scale, these benefits of modular technology will significantly influence your company’s bottom line. Projects of this nature are notoriously expensive. Experts estimate that over 80 percent of the cost associated with Deepwater developments is linked to installing platforms offshore versus drilling wells from fixed platforms. Given the fixed nature of the latter type of platform, it is clear why having a more efficient means to deploy equipment would be a major advantage.

3) Keep Infrastructure to A Minimum

By combining equipment into modules that can be quickly assembled or taken apart, field development plans can take advantage of the best possible solutions at any given time. In general, this approach is much more flexible than stabilizing an entire platform in one location and will enable operators to minimize costs by reducing the size of support vessels required and the number of staff needed for supervision.

4) Enable Future Flexibility

For all projects, it’s always better to prepare for additional problems rather than hope they won’t arise. This same logic applies when investing in modular technology. Not only would it allow you to meet specific demands from oil majors now, but you could also modify your design to meet any future requirements. You could even create a new business model that allows your company to take advantage of secondary markets in light of new research and technology.

5) Adjust More Easily to Changing Market Conditions

As previously mentioned, modular units can be re-purposed or used for additional purposes if market conditions change. For example, crane modules on the seabed could be repositioned at different locations and used as bridge foundations. This would then allow operators and service providers to recover some of their initial investment by using assets that were intended for one particular solution only.

The future is bright for the deepwater equipment industry. For many years now, companies have been making efforts to improve their products by incorporating easily replaceable hardware components and software features that allow them to upgrade without making large design changes or purchasing new products. This trend toward modularity is growing due to the benefits it provides for both consumers and manufacturers.